What is Silvering? (#55)

It occurs when laminating overlaminate to print. It is very noticeable in the dark shadow area of the print.

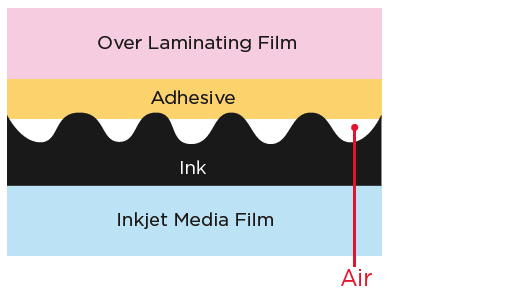

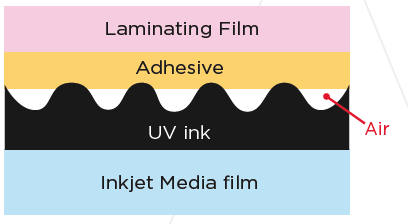

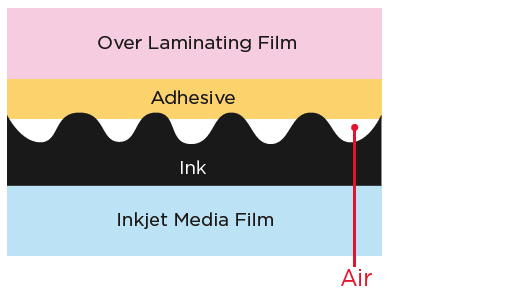

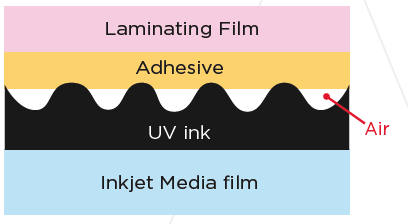

Silvering occurs when tiny air bubbles are captured between adhesive and ink:

Possible Reasons for Silvering Occurence

- Insufficient roller pressure – Improper downward pressure between the laminator rollers and uneven roller set up (Low cost, hand crank laminators) often cause silvering.

- Laminating speed too high – Lowering the laminator speed allows for more time for pressure to be applied to the laminate, thus sealing the air bubbles on the print. In general, the optimal laminating speed for pressure sensitive laminates is 2-5 ft/min.

- Uneven graphics surface – Uneven graphics surface may be caused by the media (fiber base media, canvas) or ink (UV digital ink, screen printing ink).

- Thinner adhesive coat weight – A thicker adhesive coat weight can fill in the area between the print and the overlaminate.

- Hard adhesive – A softer adhesive can also fill in more of the area between the print and the overlaminate.

- Rigid overlaminate film – A soft overlaminate film can better conform to the topography of the print.

- Low temperature – During the winter, some regions may drop below -32°F. Silvering may occur due to the overlaminate film and adhesive hardening at lower temperatures. Room temperature (74°F) is recommended for printing and laminating.

Adhesive Wet Out on Digital Inks

In general, the overlaminate adhesive will wet out in 12-24 hours on water-based, eco-solvent, solvent, and latex ink. With the same clear overlaminate, moderate to heavy silvering will initially occur on UV ink. Even with adhesive wet out, silvering may still occur due to highly uneven UV ink surface.

Silvering usually does not occur on Eco-Solvent ink or it wet out in 24 hours:

Silvering does not occur on Latex ink or it wet out in 24 hours:

Silvering occurs on UV ink becuase of the uneven ink surface:

Adhesive Wet Out on Digital Inks

In general, the overlaminate adhesive will wet out in 12-24 hours on water-based, eco-solvent, solvent, and latex ink. With the same clear overlaminate, moderate to heavy silvering will initially occur on UV ink. Even with adhesive wet out, silvering may still occur due to highly uneven UV ink surface.

Silvering/Adhesion Test on UV Ink

Today, there are many UV inks on the market, each with distinctive levels of smoothness and surface energy which contribute to overlaminate silvering and lifting. UV inks with a smoother topography and higher surface energy are more ideal for overlaminate compatibility. It is highly recommended to perform peel adhesion tests and silvering analysis of the overlaminate on the UV ink before beginning production. Even though silvering occurs on UV inks, overlaminates may still adhere well.

Hot Roll Lamination Guideline

Heat assistant may help minimize the amount of silvering. Recommended settings for hot roll lamination:

- Set the heat setting on the pressure roller at 125°F.

- Increase the roller pressure to at least 50 lbs/in2.

- Slow down the roller speed to 2ft/min.

Disclaimer

The hot roll lamination guideline is based on the result obtained from a test laminator model. Your laminator model may require a different setting. Arlon makes no warranties on silvering improvement for hot roll lamination due to UV ink topography.

Europe, Middle East, Africa, India | English

Europe, Middle East, Africa, India | English

North America | English

North America | English Latin America | Español

Latin America | Español Latin America | English

Latin America | English Australia, New Zealand | English

Australia, New Zealand | English Asia | English

Asia | English Europe, Middle East, Africa, India | English

Europe, Middle East, Africa, India | English Europe, Middle East, Africa | Français

Europe, Middle East, Africa | Français Europe, Middle East, Africa | Italiano

Europe, Middle East, Africa | Italiano Europe, Middle East, Africa | Deutsch

Europe, Middle East, Africa | Deutsch Europe, Middle East, Africa | Polski

Europe, Middle East, Africa | Polski Brazil | Portuguese

Brazil | Portuguese